Nonlinear stability and dynamics of nonisothermal film casting

Researchers Li Liangbin and PhD student Tian Fucheng of our laboratory used a self-developed non-Newtonian fluid finite element solver to study the instability of draw resonance flow during film casting. Related work was published in the recent Journal of Rheology.

Film casting is a method commonly used in the industry to produce polymer films. Studying the flow instability of the project and establishing a stable processing window have important guiding significance for industrial production. In the past, studies on the film casting mainly focused on the steady state. The analysis of the instability of the non-steady state was less, and most of them adopt simple viscoelastic constitutive equations, such as the UCM model, which cannot truly predict the flow stability. In addition, due to the limitation of the High Weissenberg Number problem(HWNP), the Deborah numbers achieved by previous calculations are relatively low. In our work, we used advanced DEVSS and SUPG algorithms, which greatly improved the stability of the algorithm. At the same time, a well-known Phan-Thien and Tanner differential viscoelastic constitutive equation has been employed to analyze the nonlinear stability and dynamics of nonisothermal film casting.

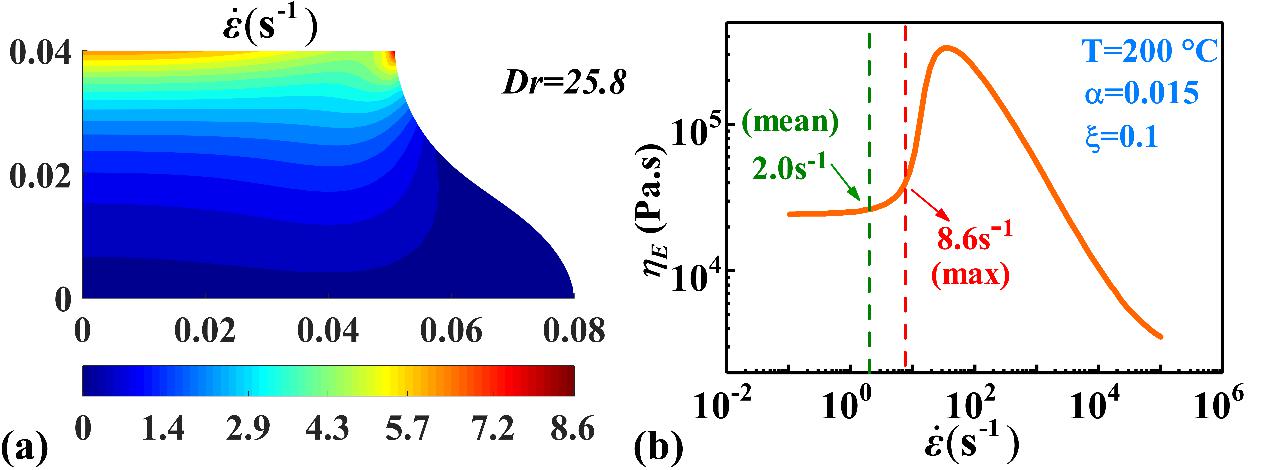

Our results show that increasing extensional viscosity stabilizes flow for both extensional thickening and extensional-thinning fluids. The stability of the system at first is always enhanced and then weakened with increasing relaxation time or the extrusion rate, whereas the cooling polymer film always leads to stabilizing effects, which can be attributed to the variation in extensional viscosity (As shown below). Two distinct Drc maxima are observed with the variation of the AR of the film, which can be attributed to different deformation modes varying with AR.

The contour map of the extensional strain rate with h =0.04m,W=0.08m under onset (Drc=25.8) conditions. (b) The evolution of extensional viscosity with strain rate for extensional-thickening fluids at T =200 ℃.

This work was supported by the Key research and development tasks of MOST (2016YFB0302501) and the National Natural Science Foundation of China (Nos. 51633009 and 51325301).