Deformation of Ultrahigh Molecular Weight Polyethylene Precursor Fiber: Crystal Slip with or without Melting

Professor Liangbin Li and doctoral candidate Fei Lv et al. of our lab systematically studied the structural evolution of ultrahigh molecular weight polyethylene precursor fiber at different temperatures with home-made temperature jumping extension rheometer. This work was published in recent Macromolecules (2017, 50, 6385−6395).

Ultrahigh molecular weight polyethylene (UHMWPE) fibers, due to their outstanding mechanical performance properties, self-lubrication, low-temperature resistance and biocompatibility, have been widely applied in various fields. And our work can semi-quantitatively reveal the coupling effect of and temperature and external stretching field.

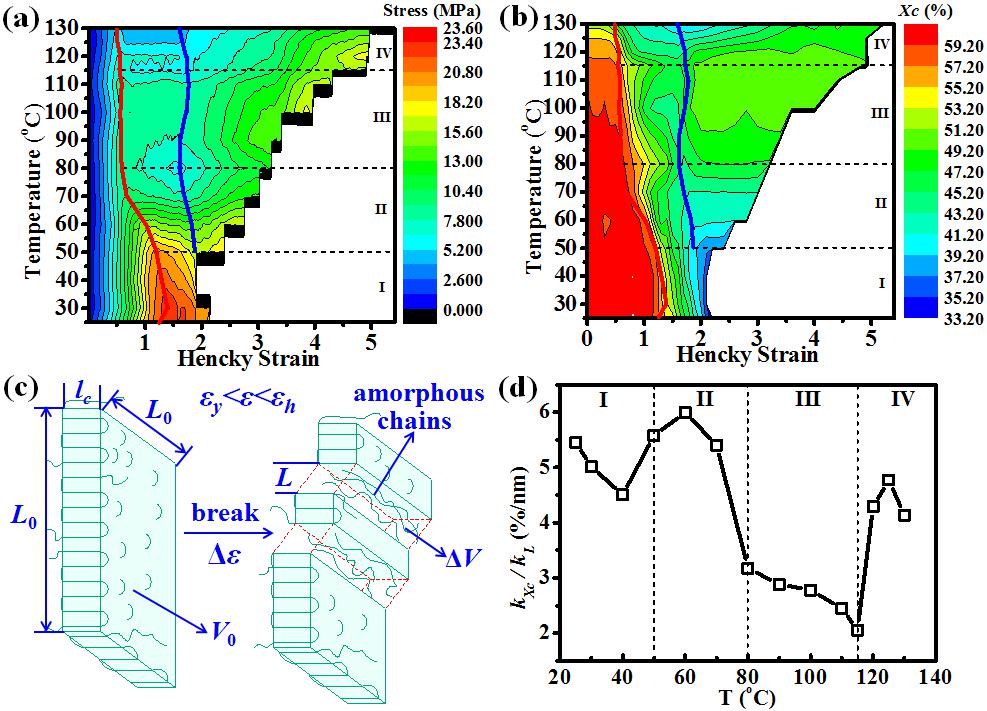

According to the result of dynamic mechanical analysis measurement (DMA),the temperature space can be divided into four temperature regions (I、II、III、IV).The evolution behaviors of stress-strain curves and structures (crystallinity Xc, crystal size L200, the content of oriented crystal OC) during deformation are discrepant in different temperature regions. Crystal will break into pieces due to external field (the decrease of crystallinity), and crystal size will decrease gradually owning to the fact that part volume of crystal will transform into amorphous area. According to the schematic illustration of the break of crystal as well as the ratio between the decreasing slope of crystallinity (kXc) and the decreasing slope of crystal size (kL), we can semi-quantitatively reveal the coupling effect of and temperature and external stretching field during deformation. When we regard the crystal-amorphous transformation process as nucleation process, the influence of temperature and external field on nucleation density (n) and critical nucleus size (L) is discrepant in different temperature regions. And that is why the structural evolution and mechanical behaviors are discrepant in different temperature regions.

This work is supported by the National Natural Science Foundation of China (51325301, 51633009).

(a) Contour maps of stress-strain curve at different temperatures. (b) Contour maps of crystallinity at different temperatures