Structural Evolution of Hard-Elastic Isotactic Polypropylene Film during Uniaxial Tensile Deformation: The Effect of Temperature

The effects of temperature on the non-linear mechanical behaviors of hard-elastic isotactic polypropylene films are systematically studied with in-situ ultrafast synchrotron radiation small- and wide-angle X-ray scattering techniques (SAXS/WAXS) during uniaxial tensile deformation at temperatures from 30 to 160 C. The related work has been published in Macromolecules (2018, 51(7): 2690-2705).

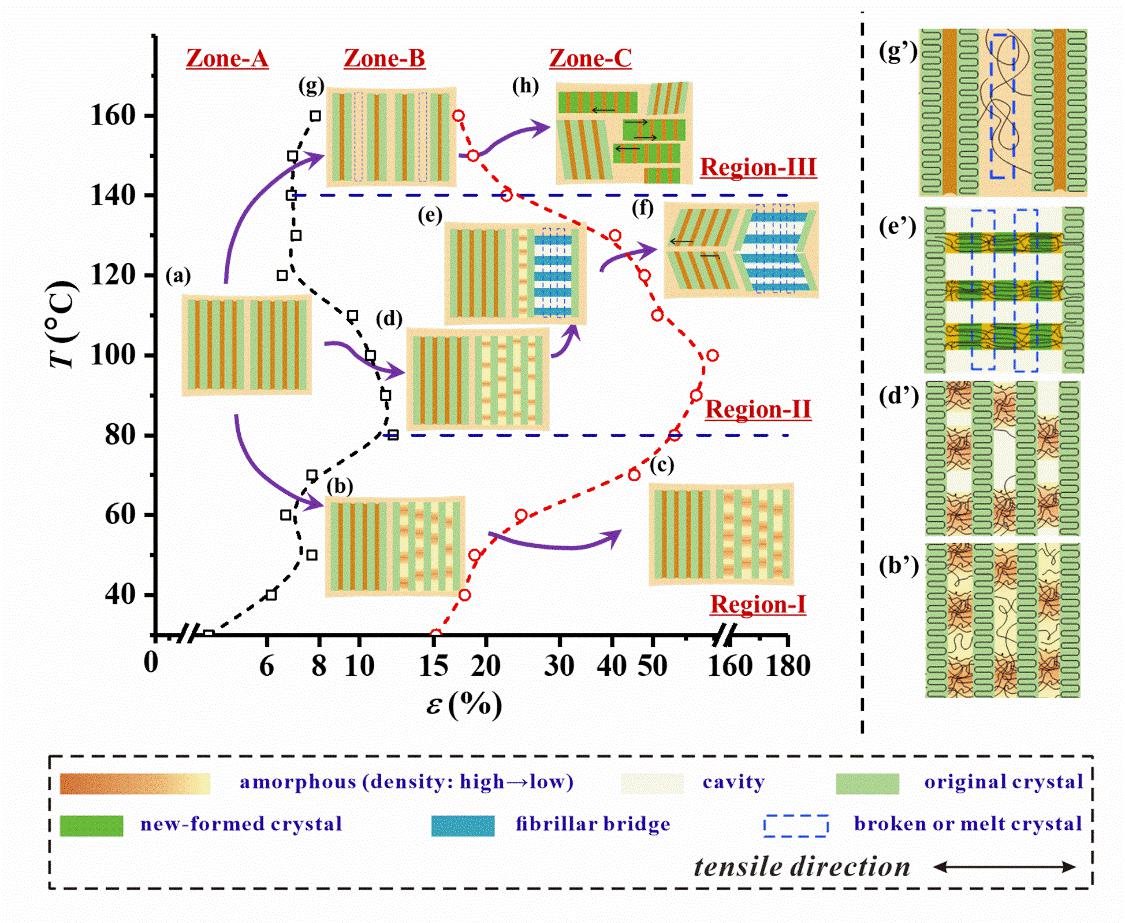

Based on the mechanical behaviors and structural evolutions in strain-temperature two-dimensional space, three temperature Regions (I, II and III) are clearly defined with the α relaxation temperature (Tα≈80 C) and the onset of melting temperature (Tonset≈135 C) as boundaries, respectively, where different mechanisms dominate the nonlinear deformations after yield. In Region I, micro-strain in lamellar stacks εm obtains an accelerated increase after yield and reaches a value significantly larger than corresponding macro-strain ε, during which neither slipping, melting nor cavitation occurs. We propose stress-induced microphase separation of interlamellar amorphous to be responsible to the hyperelastic behavior in Region I. Above Tα in Region II, due to reduced cohesive strength and enhanced chain mobility, the irreversible reduction of crystallinity and the formation of slender cavities suggest that crystal slipping overwhelms microphase separation and plays the major role in nonlinear deformation, during which chains in lamellar crystals are pulled out and recrystallize into nanofibrillar bridges. In Region III above Tonset, melting-recrystallization dictates the nonlinear deformation. A schematic roadmap for structural evolution is constructed in strain-temperature space, which may guide the processing of microporous membranes for Lithium battery separators as well as other high performance polymer fibers and films.

The schematic images of the deformation mechanism in hard elastic iPP films in the wide temperatures range (30-160 °C).