he review article entitled with “Recent Advance in Post-stretching Processing of Polymer Films with In-situ Synchrotron Radiation X-ray Scattering” has been published in Soft Matter.

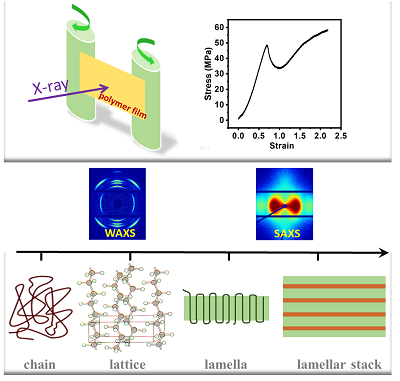

The stretch-induced structural evolution mechanism is a long-standing scientific question in the post-stretching processing of polymer films. X-ray scattering, especially a combination of small- and wide-angle X-ray scattering (SAXS/WAXS), provides a powerful method to study the hierarchical structure of polymer films. Recent advance in synchrotron radiation (SR) light source and detection technique allows to measure structural evolutions of polymer films during post-stretching processing in real time with ultrahigh time resolution, which benefits the understanding on this topic. This review summarizes some recent investigations on post-stretching processing of polymer films, which combines the in-situ X-ray scattering techniques with the purposely designed tensile apparatus from the three aspects: uniaxial stretching, biaxial stretching and stretching with chemical reaction. Concerning the polymer bulk, the traditional deformation mechanisms like stretch-induced crystallization (SIC), crystal slipping, phase transition and melting-recrystallization are discussed for the uniaxial and biaxial post-stretching of polymer films. New deformation models are developed to focus on the structural evolution in the length scale of lamellar stacks, which considers the potential microphase separation of interlamellar amorphous phase and microbuckling. For the solution system, the coupling effects of the mechanical work from external force and the chemical potential from possible chemical reaction are taken into account for the structural evolutions during stretching in solution. The roadmaps of structural and morphological evolutions in the processing parameter space (i.e., temperature, stress, strain and the concentration of additive in bath solution) are eventually constructed for precursor films. The accumulation of the structural evolution database, for post-stretching processing of polymer films, can be expected to provide the helpful guide to the industrial processing for high-performance polymer and material innovation films in the near future.

This work is financially supported by the National Key R&D Program of China (2016YFB0302500 and 2018YFB0704200) and the National Natural Science Foundation of China (51903091, 51633009 and 51890872).

Related links: https://pubs.rsc.org/en/content/articlelanding/2020/sm/c9sm02554e/unauth#!divAbstract