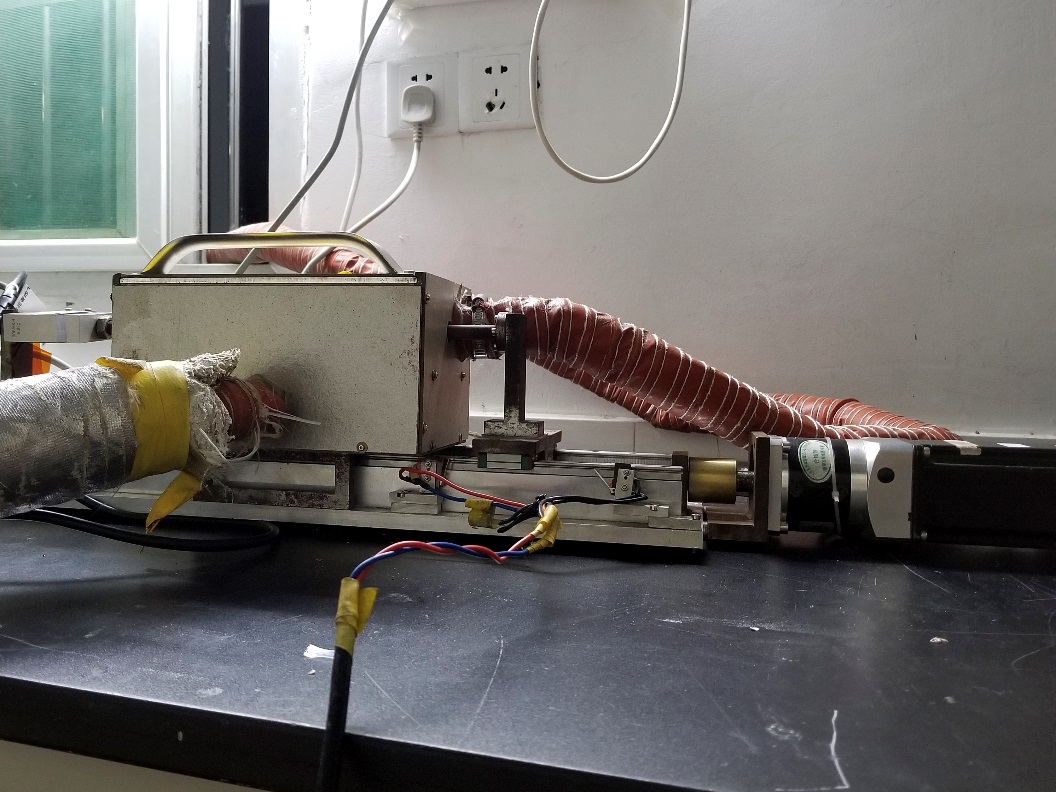

Constrained uniaxial tensile apparatus

A simple constrained uniaxial tensile apparatus was designed and constructed to obtain stress-strain curve during stretching and subsequent structural evolution of polymeric films. Stretch is carried out through motor driven clamps in the machine direction and the other clamps in the transverse direction keeping the sample width constant. The force information during film stretching process is recorded by a tension sensor and structural evolution can be obtained by in situ X-ray scattering technique. All parameters related to film stretching manufacturing, such as temperature, draw ratio, and stretching speed can be set independently, making the apparatus an effective method to explore the relationship between processing parameters and structure.

FIG Constrained uniaxial tensile apparatus

Tab Performance specifications

mm/s | Max strain rate mm/s | Processing temperature ℃ | Min length of sample mm | Max strain |

| | 10 | Room temperature-200 | 20 | 5 |