Film Blowing

Film blowing is a successive process involving a variety of processing steps and machining parameters, during which stretching induced nonlinear rheology, crystallization and deformation/phase transition of crystallites occurs. The rapid evolution of multi-scale structures and the coupling of various machining parameters make it challengeable to experimentally study the fundamental non-equilibrium scientific questions. In view of the complexity of the film blowing, we develop a homemade film blowing machine to study the structural evolution of polymers during film blowing by using an in-situ synchrotron radiation small- and wide-angle X-ray scattering. By studying the rheology of polymers, the crystallization during film blowing and the properties of blown films, the relationship between the molecule parameter- the external field-the structural evolution and the film properties is established, which is important to understand the non-equilibrium physics under the strong external field during film blowing and provides an optimization program of the processing parameters for the produce of high-performance film.

Polymer crystallization under strong external field

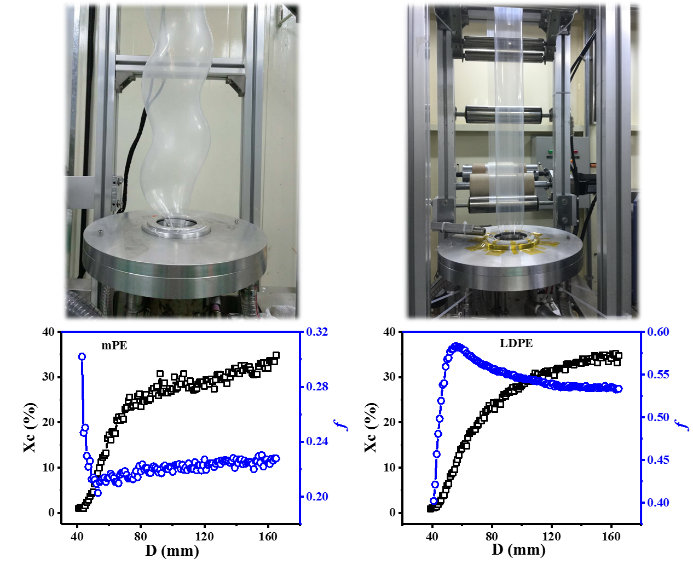

Film blowing is one of the most important polymer processing technologies。It is extensively used to produce packaging films, protective films and agriculture films. During the film blowing, strong flow field and high cooling rate are imposed on the polymers, which causes the complexity of crystallization. As these two external fields are intimately coupled with each other, it is a challenge to elucidate their specific roles on crystallization, film stability as well as the final properties of film products. In this sense,in-situ small- and wide-angle X-ray (SAXS and WAXS) measurements during film blowing of PE film are employed to investigate the crystallization of PE under such strong external field, which is important to understand the non-equilibrium physics under the strong external field during film blowing and provides a guidance for improving the bubble stability and the properties of the film.

Qianlei Zhang, Lifu Li

Haoyuan Zhao, Youxin Ji

Modified PE Blown Film

The manufacturing of the blown films is one of the complex processes for polymers which have received attention recently for both the practice and research point of view. Despite of the much research efforts the distinct understanding of the molecular parameters which decide the valuable properties of the blown films such as haze, transmittance and the wettability are not fully formulated. The underlying question is to explore the structural behavior of modified polyethylene during processing through blown films, and the interpretation of optical and wettability of resulting blown films. We have used the powerful tool of synchrotron radiations based in- situ Small- and Wide- angle scattering (SAXS and WAXS) along with the temperature sensor to explore the microstructural analysis. The haze and transmittance measured by the haze and transmittance meter for the optical properties and the contact angle tested by the goniometer for the wettability. According to the prescribed quality, for the modified polyethylene, we have used various composition of the ionomers (polyethylene methacrylic acid) and the hyperform nucleating agent (HPN 20E). Both of these materials have greatly influenced the microstructural features, haze and wettability.

Sarmad Ali, Youxin Ji

PBAT Biodegradable Film

Plastic film is widely used in agricultural production. The lack of degradability of traditional film such as polyethylene (PE) has caused great harm to soil and crops. Poly(ethylene terephthalate)/butylene adipate(PBAT) has become an alternative material because of its excellent degradability. However, during the blowing process of PBAT, the bubble is unstable. Therefore, we modified the PBAT by adding chain extender (ADR) to prepare PBAT materials with different molecular chain lengths. In situ Wide-angle x-ray and Small-angle x-ray diffraction techniques were used to study the structural evolution of PBAT bubble from the exit die position to the frost line position by using a home-made lift and blown film machine. Meanwhile, we used” particle tracking technology” to capture the distribution of the flow field on the outer surface of the bubble and calculated the strain and strain rate along the machine direction (MD) and traverse direction (TD). The results showed that the orientation of the lamellae in the PBAT bubble had a different tendency compared to that of PBAT/ADR bubble. The distribution of strain and strain rate on the outer surface of the bubble of both PBAT and PBAT/ADR blends obtained by the” particle trace method” is the same. Along the MD direction, the strain rate of the PBAT and PBAT/ADR blends steeply decreased after a sharp increased. The strain rate in the TD direction is much smaller than the strain rate in the MD direction. We believe that the distribution of the strain and the strain rate of the external flow field mainly depends on the constant tension in the MD direction and the pressure difference between the inside and outside of the bubble. In the PBAT film blowing process, the molecular chain had no response to the external flow field near the die exit while in the PBAT/ADR film blowing process, rapidly orientation appeared in the MD direction, indicating that the obvious response of molecular chains to the external field. This work elucidates the structural evolution mechanism of PBAT and PBAT/ADR blends in the blown film process and reveals the role of molecular chain length in the blown film process of PBAT, providing the theoretical guidance of producing and processing of agricultural plastic film.

Lifu Li; Youxin Ji

Effect of Molecular Parameters on Film Blowing

Linear low density polyethylene are widely used as blown film raw materials due to its excellent mechanical properties. However, in practical processing, LLDPE has higher torque and extrusion pressures and is more prone to blown film instability relative to LDPE. It is noteworthy that the stability of the blown film process will not only affect the final performance of the film, but also severely limit the rate of film production, which is essential for the film production industry.Evidently, the difference in the stability of the blown film is closely related to the molecular structure of the polymer. Therefore, it is very important to study the influence of different molecular chain parameters on the process of structure evolution and film properties. Our group selected several blown film raw materials with significantly different molecular structure parameters in an effort to clarify the process-structure-performance relationships in the blown film processing process and provide theoretical and practical guidance for industrial production.

Haoyuan Zhao, Lifu Li

Qianlei Zhang, Youxin Ji