With the development of petroleum industry and technology, polymer film is broadly applied in many fields which is originally used as packaging film and now becomes intelligent and functional. Polymer film processing group pay attention to investigating the porous membranes which have the widest uses in daily life as well as high-tech field. We also lay emphasis on optical film trying to break the technology monopoly.

Porous membranes

Porous membranes and the membrane separation technologies, including microfiltration, ultrafiltration, electrodialysis, reverse osmosis, etc., have been widely used in food, medicine and health care, biotech, chemical engineering and environment area, and play an increasingly important role. As a carrier material, multi-scale pore size porous membranes have important research value. The research of porous membrane in our group mainly focuses on the materials preparation method, the industrialization process and the improvement of application performance. At present, the main research systems are PE, PAN, PP, etc.

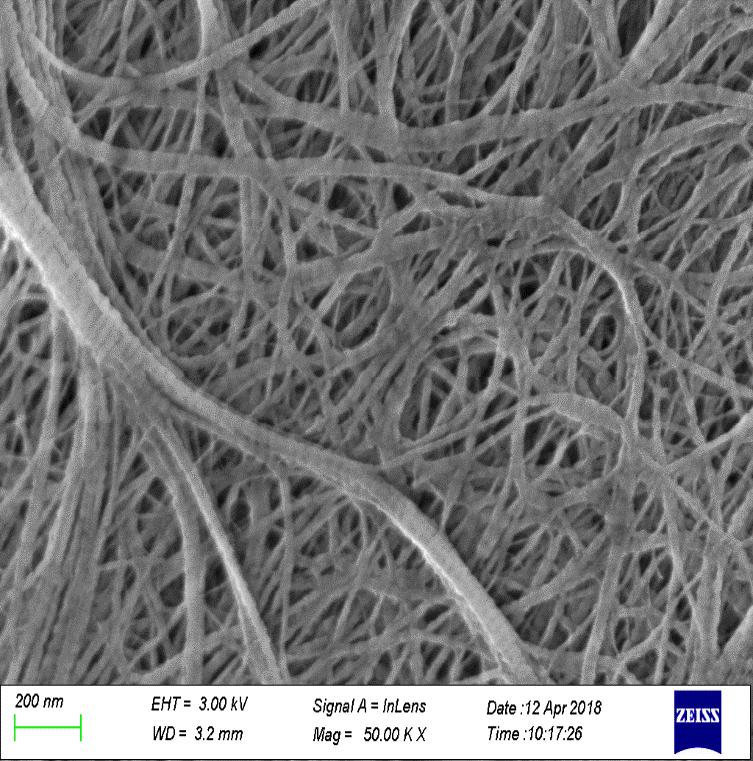

1. The porous polyethylene membrane was derived from the lithium battery separator made by wet process. By adjusting the process parameters, a porous membrane with a nanofiber network structure was prepared, which was abbreviated as nanofibrous membrane. By further modifying the hydrophilicity, it can be used in field of ultrafiltration or nanofiltration in order to expand the use of polyethylene porous membranes.

2. The porous polyacrylonitrile (PAN) materials possess excellent resistance to inert solvents, and bacterial corrosion, heat and physicochemical stability, so they have been widely used in water treatment, pervaporation, enzyme-immobilization, biological medicine, and carbon materials. Aimed at improving the performance of PAN porous membrane and further expanding its application, PAN gel membrane was prepared by using advanced thermally induced phase separation, and then stretching the PAN gel membrane to make the PAN nanofibrous membrane.

3. Polypropylene porous membranes are widely used in lithium battery separators. However, their hydrophobicity leads to poor contact with the electrolyte which influeces the passage of ions. By the organic/inorganic composite coating, the hydrophilicity of the PP porous membrane is increased, improving the contact with electrolyte.

Caixia Wan, Xin Chen, Yahui Li

Design and synthesis optical polymers:

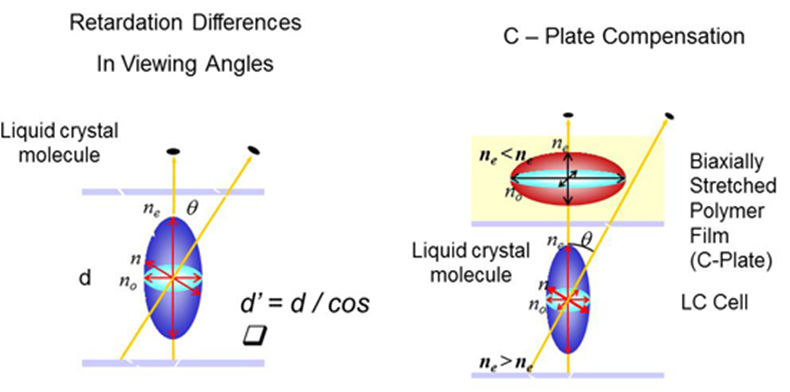

Optical compensation film are key components to realize the display performance in wide-viewing angle for all the LCD modes.Methacrylate polymers have promising application prospects as emerging materials for optical compensation film in recent years.

Based on the inherent optical anisotropy of different small molecules, we synthesised the optical polymers by copolymerization method in order to achieve molecular design and structure regulation.A series of processing processes such as knife coating and stretching orientation are then performed on the resulting optical polymer to fabricate an optical compensation film with a specific retardation compensation value and wavelength dispersion.

There are mainly two synthetic routes at present: the first one is based on PMMA, BzMA and MMA with positive and negative intrinsic birefringence, respectively, are randomly copolymerized; on the other hand, based on p-methoxybenzoyl chloride, dihydroxytoluene and methacrylic acid, a shell-type liquid crystal polymer having a positive birefringence was synthesized.

Qi Yan, Fei Zhong

Optical polymer processing

Optical polymer film apply in many fields which include automotive, aerospace, lighting, telecommunications, fire protection, security, electronics and military sectors. We hope to gather experience across the whole of the optical polymer film processing from molecular designing to material molding, especially in such aspects:

Optical polymer film apply in many fields which include automotive, aerospace, lighting, telecommunications, fire protection, security, electronics and military sectors. We hope to gather experience across the whole of the optical polymer film processing from molecular designing to material molding, especially in such aspects:

(1).Specialist molecular design

(2).Product and process development

(3).Optical moulding and product finishing processes

(4)Multilayer polymer assembly

Ke Ye, Wenwen Zhang